Just a few small design revisions, just further refining and optimizing screw usage.

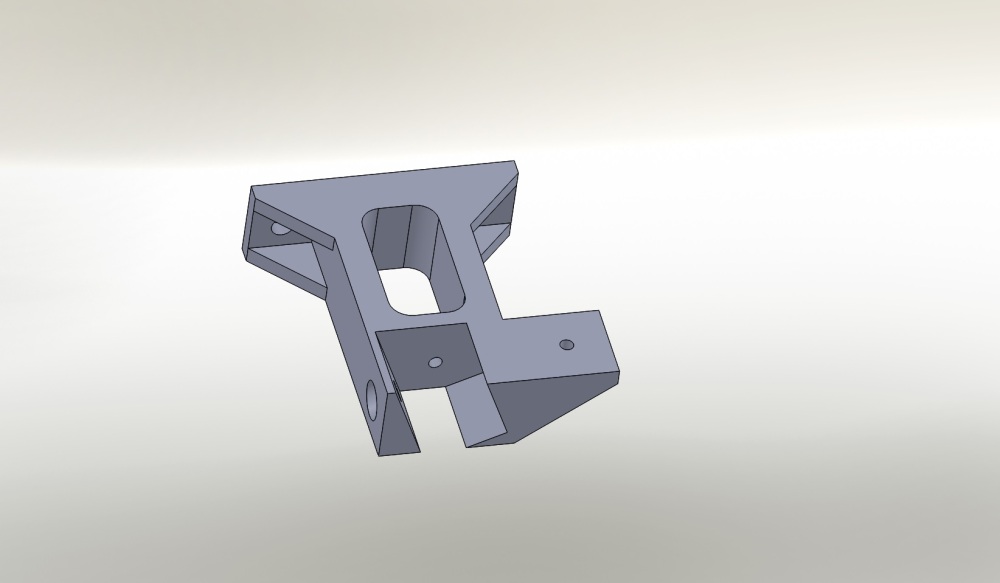

Starting off, this is the slightly new redesigned bottom cross brace mount, the opening in the center has been lengthened to fit larger allen wrenches to tighten the M3 screw which prevents rotation around the X-axis. The mount on the right that mounts to the 150mm Alu. extrusion has changed from a M5 screw to a M3 screw.

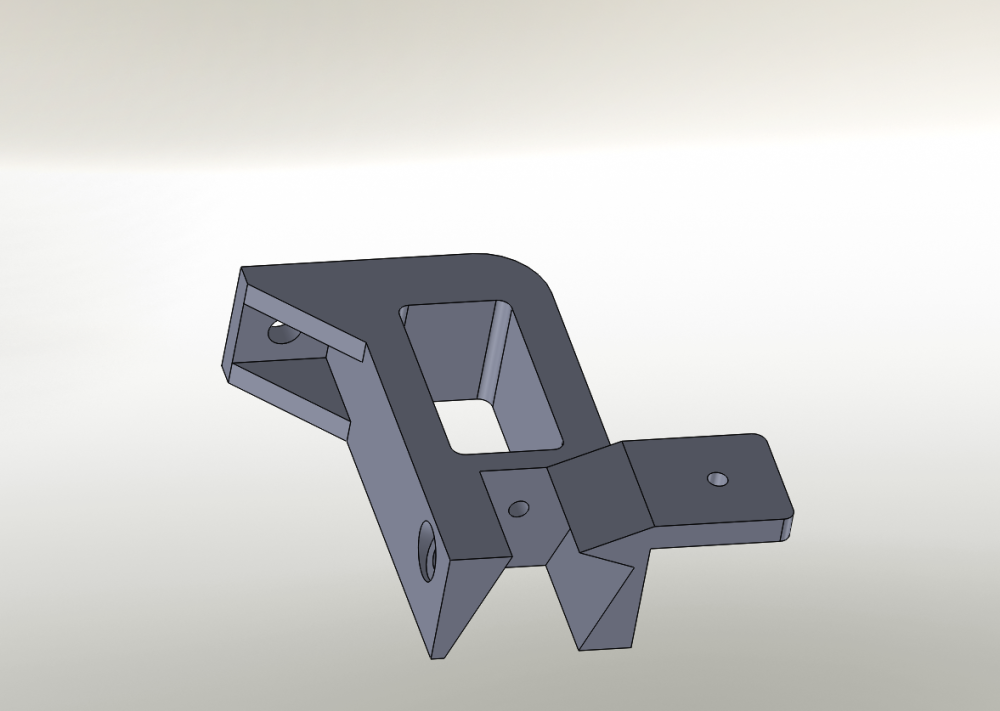

The M8KX Top brace mount also received the same updates as the bottom crossbrace mount.

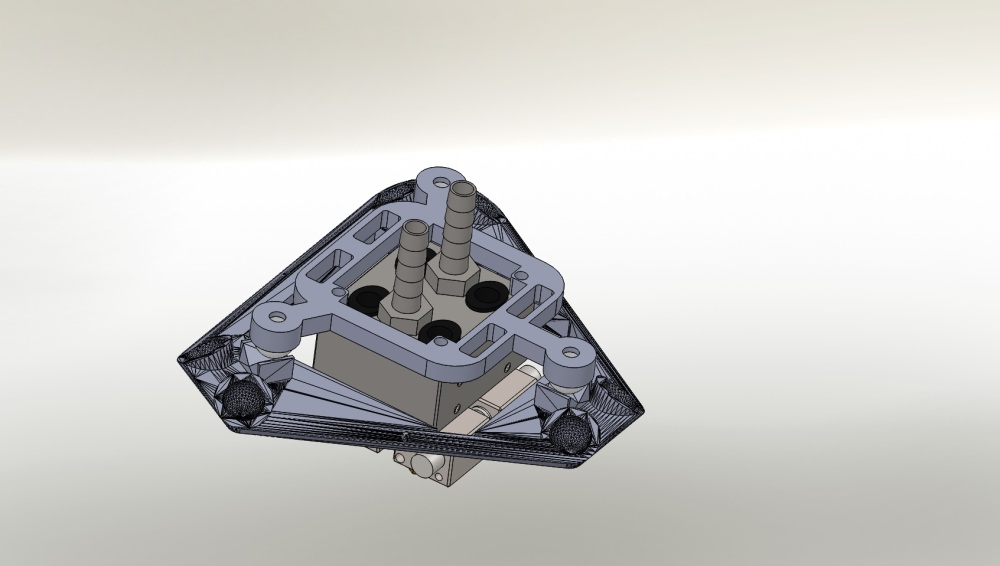

Now this one took quite a long time to update, but it is slightly difficult to see, so I’ll try my best to be as detailed as possible. I revised the Kelvin Kinematic Mount design to increase its repeatability. Previously, the mount design used a 60-degree V-groove design. Now it uses a 90-degree V-groove mount which still retains strong magnetic force while also increasing repeatability. The original Kraken mount had the Kraken Hotend sit higher in the effector which was great for maximizing print height. However, this also made the Dual IR sensor that is attached to the effector to extend below the nozzle. This was a large issue coupled with the original design blocking access to the set screws on each heater block which made individual leveling of the heater block impossible. Now the Kraken sits in the center of the effector wich direct access to the set screws.

By integrating the Kelvin V-grooves into the effector, it reduced the number of prints, inserts, and screws that need to be mounted to the effector which also reduces the weight of the effector which will increase speed and increase quality while at the same time decreasing ringing in prints.

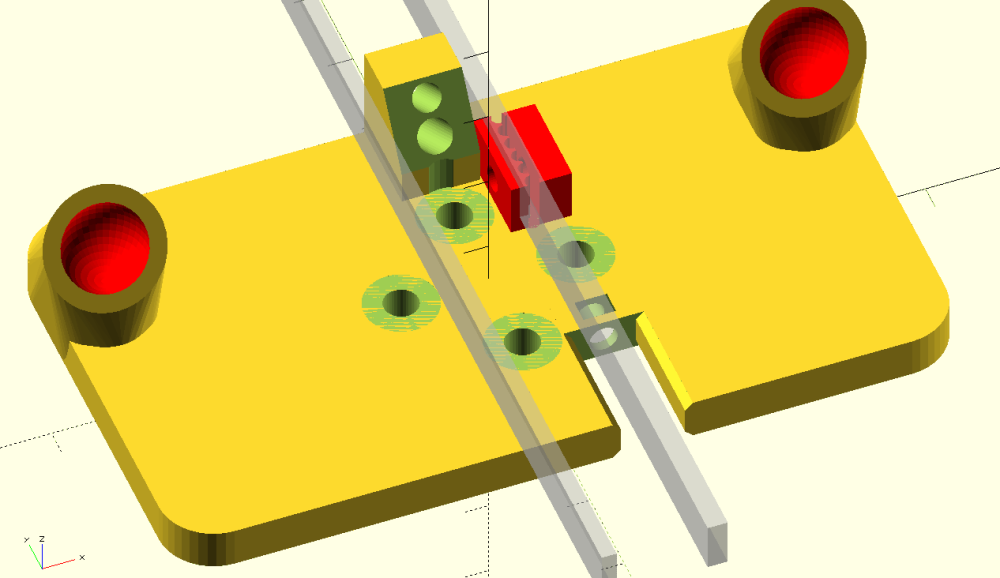

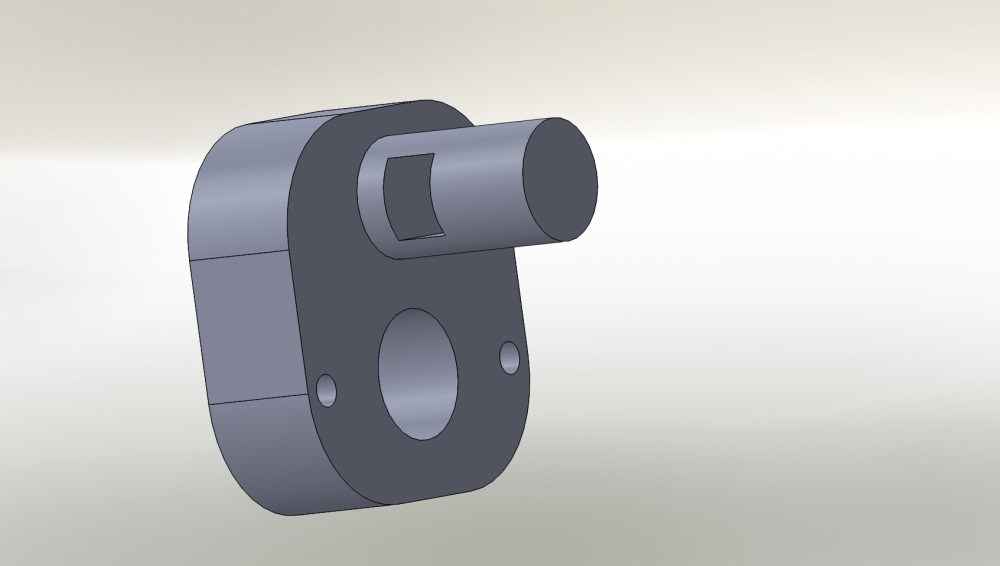

This was finally a solution I believe that will solve the convenience issue I was having. A spring-tension effector is a very efficient and strong method to connect carbon fiber rods to the delta carriage and effector. However, it also usually requires a strong tension string that needs to be compressed hard to insert and remove rods. It also requires fairly accurate lengths of tension wire to maintain a high level of tension. Instead, I wanted to use a simple screw tightening design just as I did for the belt tension.

The solution presented here uses a M3 screw that attaches to the M8KX delta carriage threaded with a M3 insert. The two ends of the wire feed through the small hole and will tie off in a double fishermen’s knot.

The new corner extrusion mount has been simplified made to be over 10 times more efficient that the original design using polymers and utilize threaded inserts to be more aesthetically pleasing.